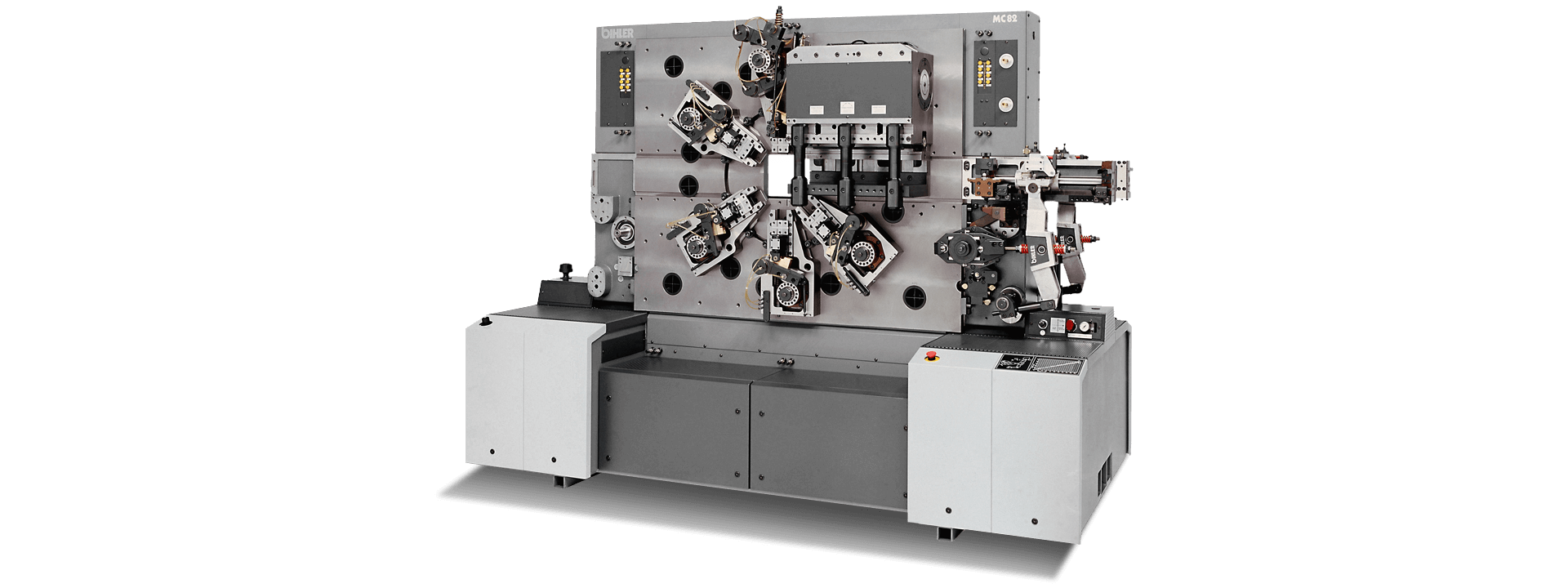

Powerful machine system with two processing faces for mass production of larger stamped and formed parts and sub-assemblies

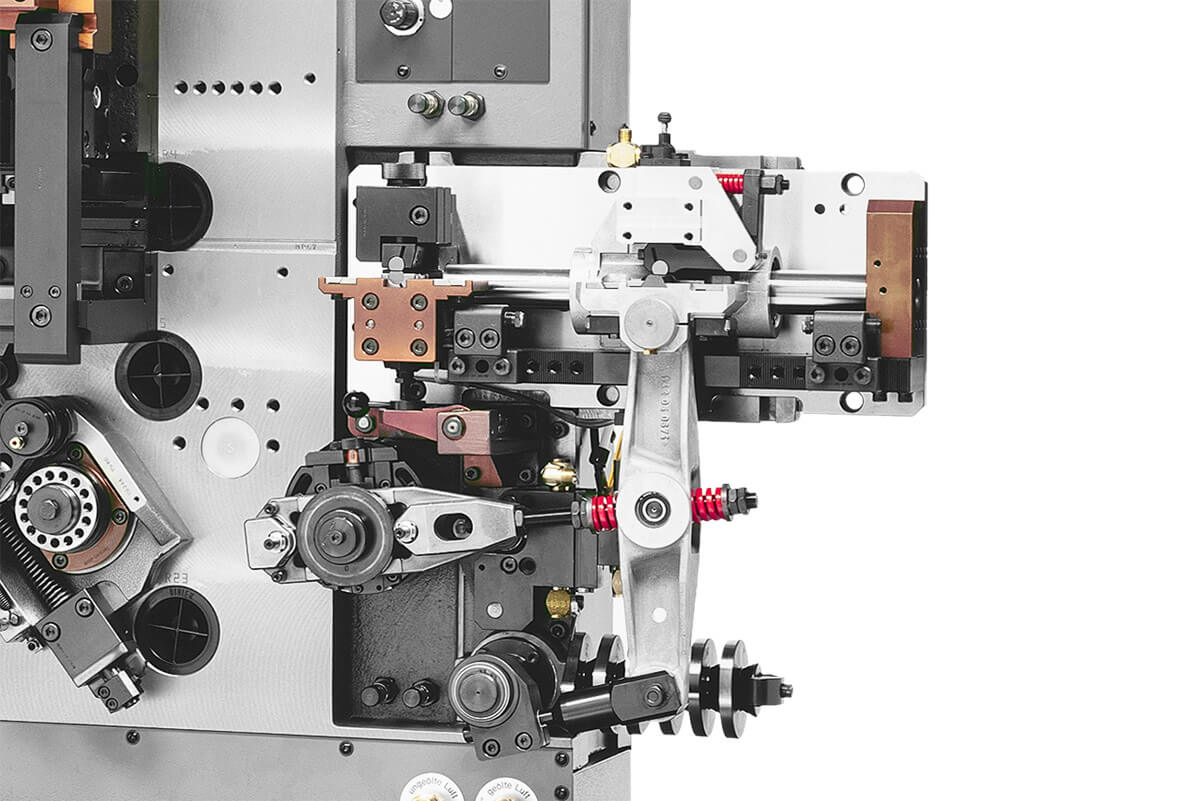

- Highly productive manufacture of complex products with simultaneous production of the individual parts

- High production speeds up to 250 1/min.

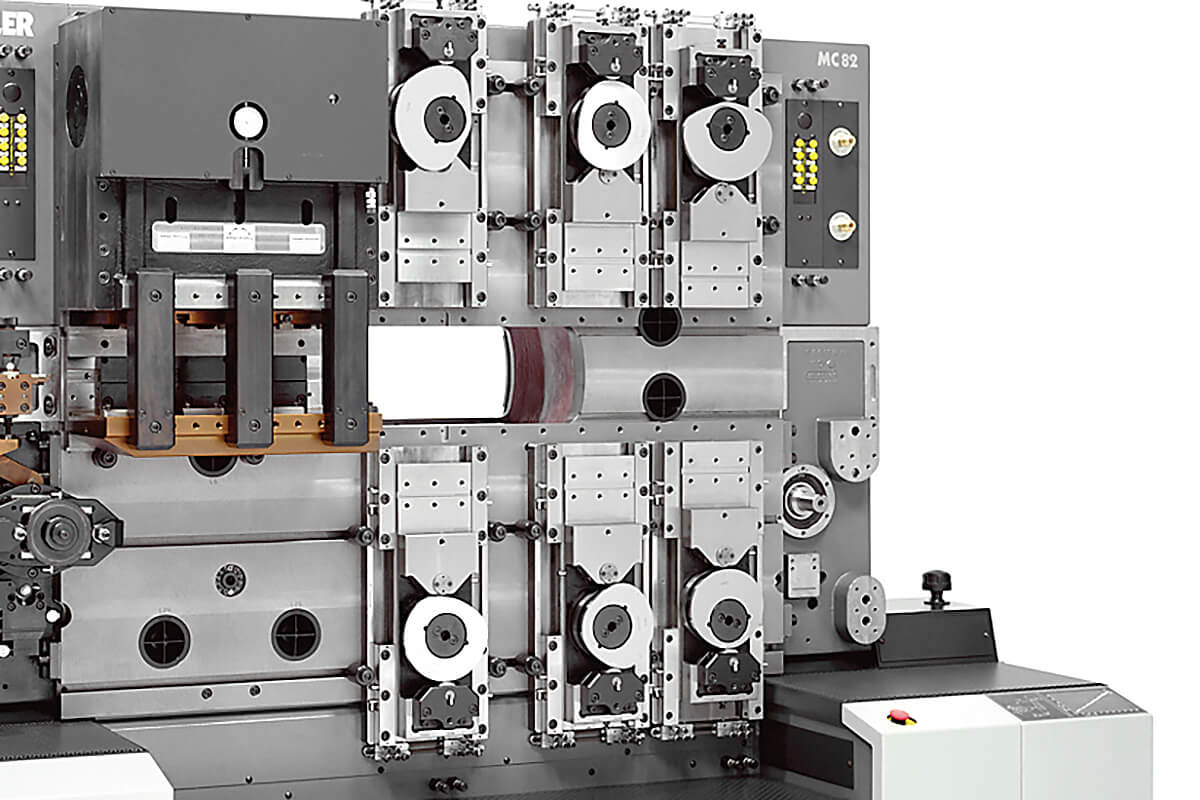

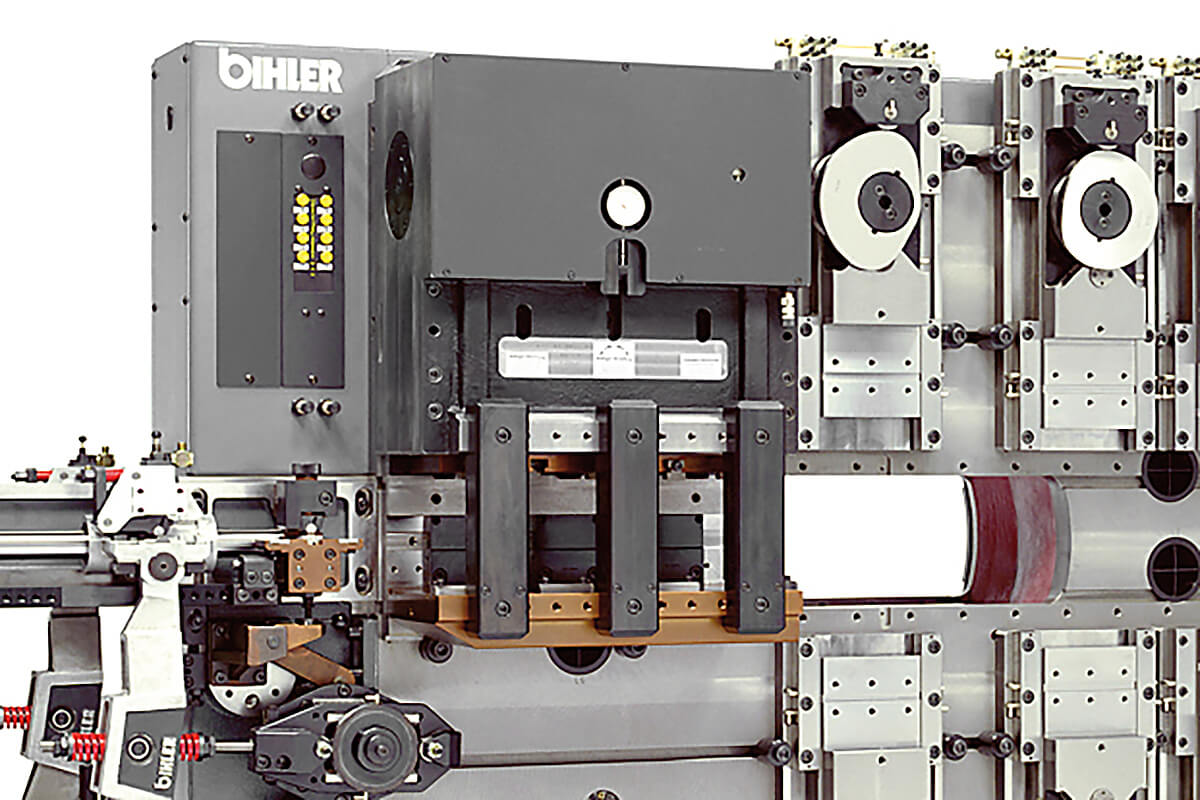

- Large opening in the center for variable transverse movements

- High degree of availability owing to rapid tool changeovers and short resetting times

- Free access to all tool stations facilitates setting up, adjustment and servicing

- Easy and secure operation with VariControl VC 1