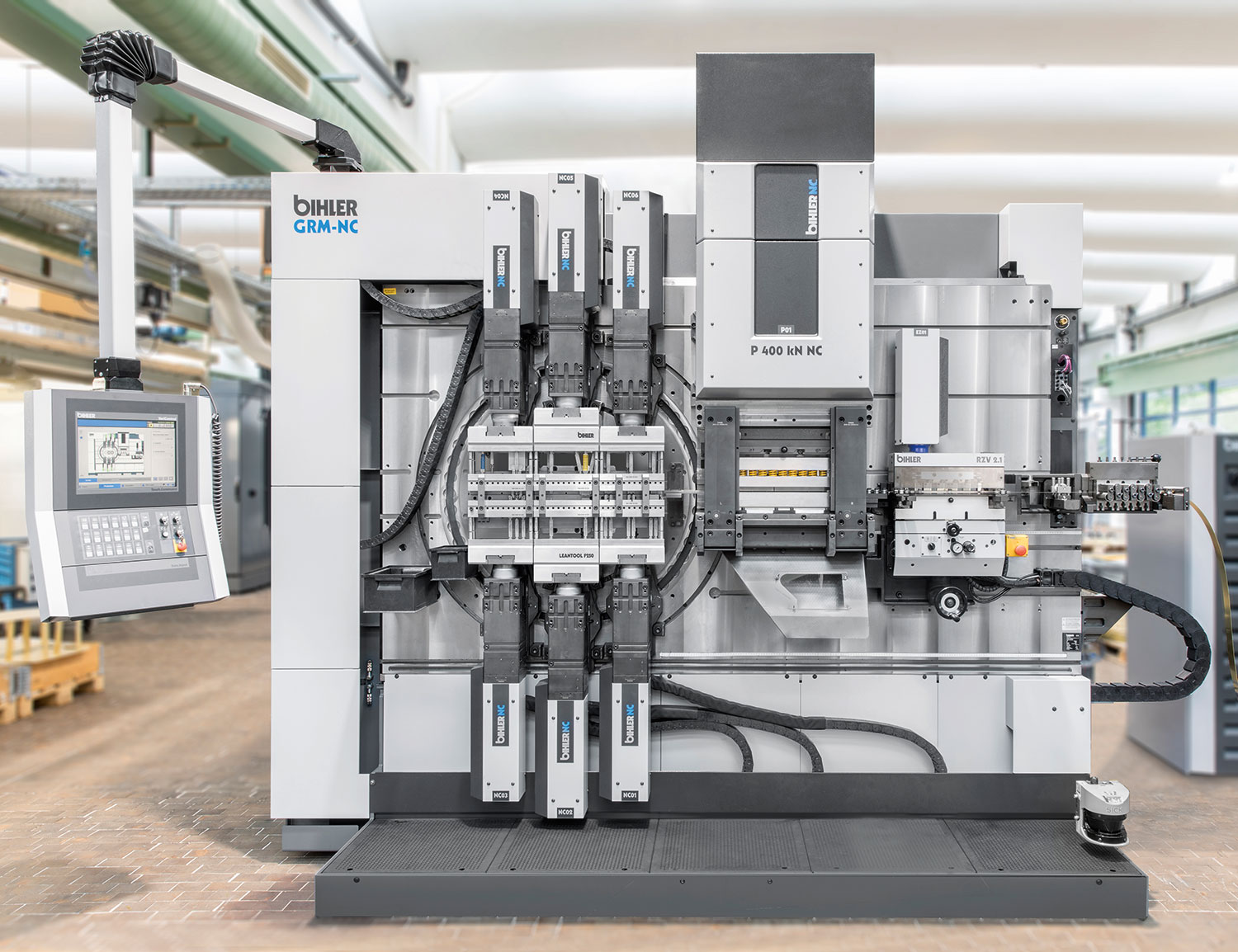

The Bihler Group of Companies offers unique manufacturing solutions for the modern industrial setting. Manufacturers of metal presses and similar industrial products have worked with our systems for decades, benefitting from their combination of precise machinery and custom module additions.

Industrial manufacturers can achieve innovative and unique designs for their parts and products by integrating Bihler systems into their existing setups or replacing them entirely. You’ll find these systems in use worldwide, dominating industrial manufacturing plants that produce:

In today’s fast-paced manufacturing environment, you must find new ways to streamline your operations to remain competitive. Increasing efficiency expands your capacity for profit. Industrial IOT smart manufacturing should be one of your solutions.

IOT represents the convergence of informational technology (IT) and operational technology (OT), changing how systems interact with one another. Utilizing wireless sensor systems and reliable 5G-capable devices can revolutionize manufacturing speeds and safety levels throughout your plant, boosting efficiency in developing everything from lighting fixtures to canning products.

Bihler develops process optimization features beyond IOT systems. Talk to a representative about other automation solutions that collect new insights from production data for your use.

Maintaining an adequate supply of materials and products requires end-to-end communication. You have to know how much raw material you have left, how many projects are mid-creation and what your stock of final products consists of. If these numbers aren’t closely managed, you run the risk of over- or under-production that cuts into your profit margins.

While automating your processes, IOT systems can track your facility’s productivity levels. Our supply chain management tools let you better manage your assets through all stages of production.

Regular maintenance keeps systems working at full capacity and maximizes your profit margins. Minor concerns can develop into major repair requirements overnight, bringing production to a sudden halt and resulting in downtime that affects your company’s productivity.

To prevent lost profits and extended downtime, Bihler systems utilize smart technology sensors to monitor equipment health and notify you of potential issues. These sensors will send feedback and let you know when it’s time to call a professional for maintenance or repairs before it begins affecting your results.

Any Bihler systems you choose to work with can help you manufacture your place in every customer’s daily life. From seat belt holders to fuse switches and much more, our industrial manufacturing partners leverage these technologies every day to offer custom solutions in all areas. Furthermore, our consulting services ensure you have all the knowledge you need to work and enhance your tools at a moment’s notice.

Let Bihler transform your industrial manufacturing operations with solutions for the modern era. We’ll help you find the best machines for your production processes. Our team can consult you to develop solutions that create efficient, sustainable and reliable product parts. Contact our team today to design your future.

Contact Us Today