Battery Busbars

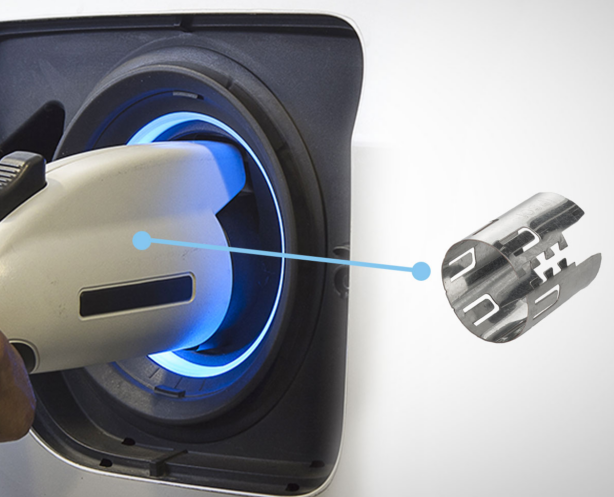

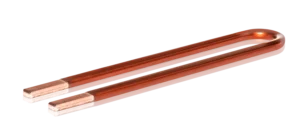

Busbars made of copper or aluminium are decisive components of powerful battery systems and the complete power distribution in vehicles.

Depending on the component length and geometry, they are produced on the GRM-NC servo-stamping and forming machine with radial or linear forming tools. For additional value-added steps, the BIMERIC servo production and assembly system offers plenty of machining freedom.

Bihler’s equipment allows for flexible, high-volume production of busbars of varying configurations. Manufacturers can realize significant material savings – up to 50% in radial production and up to 33% in linear production with lengths of over 2000mm. Tooling is cost efficient and standardized and requires very short tool changeovers ranging from 30 minutes to 1.5 hours, and with our integrated monitoring stations, you can realize consistent production reliability and quality.