The Future of Manufacturing

Bihler 4Slide-NC machines revolutionize metal forming and stamping with unmatched efficiency, reliability, and productivity. Designed to optimize your production processes, our advanced multi-slide forming technology solutions maintain high-quality standards while enhancing operational performance.

With industry-leading expertise and cutting-edge equipment, Bihler 4Slide-NC ensures increased efficiency and a maximized Return on Investment (ROI). Discover how our powerful machines and comprehensive support services can elevate your stamping, forming, and manufacturing operations.

Who We Are

Bihler 4Slide-NC, Inc. is a joint venture between Bihler of America, Inc. and Otto Bihler Maschinenfabrik, Germany—leaders in custom automation, contract manufacturing, and innovative machine solutions powered by advanced servo-controlled systems.

As a leading producer of multi-piece assemblies, Bihler 4Slide-NC combines decades of expertise in stamping, tapping, and welding with cutting-edge technology. By integrating IoT capabilities and Instant Setup features, we have transformed the four-slide manufacturing sector. Our advanced multi-slide forming machines deliver high-volume metal forming with rapid tool and die changeover, making them the ideal choice for a wide range of simple and complex applications.

Bihler 4Slide-NC also bridges the gap between traditional and modern manufacturing. Our technology is fully compatible with certain mechanical four-slide systems, filling a critical void in the market with over 30 years of advancement. Additionally, our solutions meet the highest industry standards, including compliance with IATF 16949 and ISO 9001 certifications, ensuring superior quality and reliability.

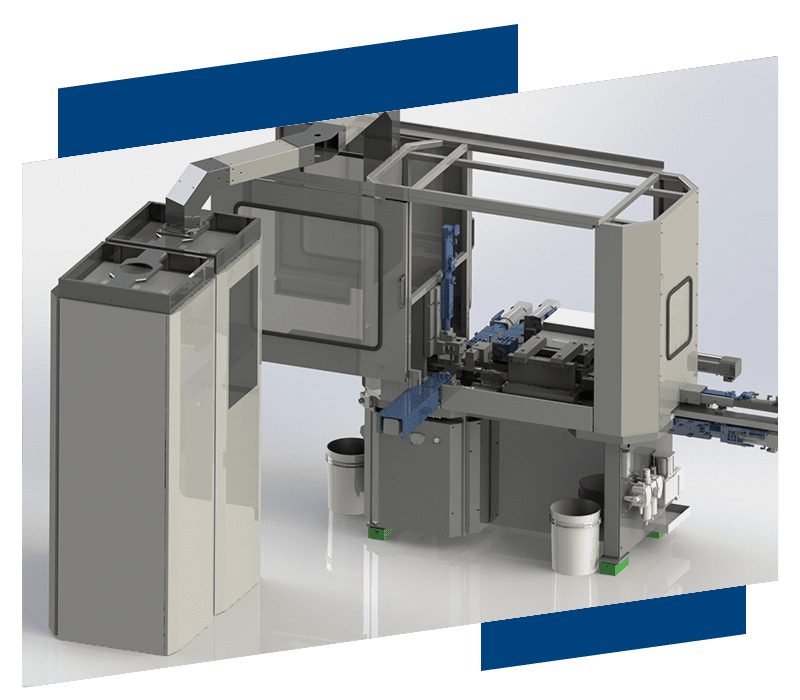

Our Machines

Our machines yield an exceptional ROI, with long-lasting value and consistent levels of increased productivity. Our four-slide engineering technology offers many wide-ranging features that benefit your operations:

Flexibility: Additional forming and stamping modules can be integrated into our four-slide system, allowing you to adapt to whatever production challenges may arise.

Compatibility: Our high-tech control system integrates with any current Bihler machine process module, providing options ranging from tapping and screw insertion, to welding and inspection capabilities.

Convenience: A touchscreen operating panel provides intuitive operation and programmable control of each servo module.

Efficiency and Capability: Our fully integrated solutions offer the ability to get higher machine output in less time, thereby increasing overall productivity for your day-to-day operations. The Bihler 4Slide-NC system typically yields higher Cpk values (the Process Capability Index) for all of the industrial processes that are run on it.

Technology

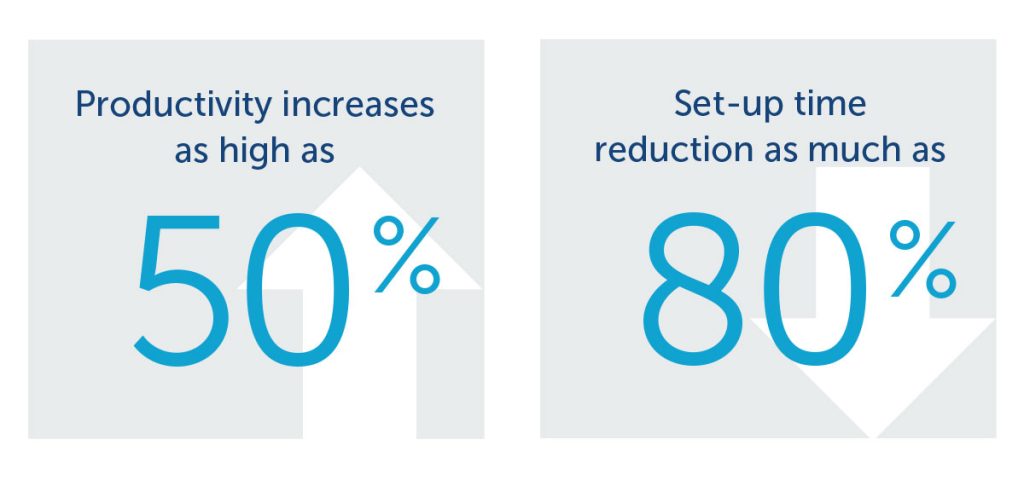

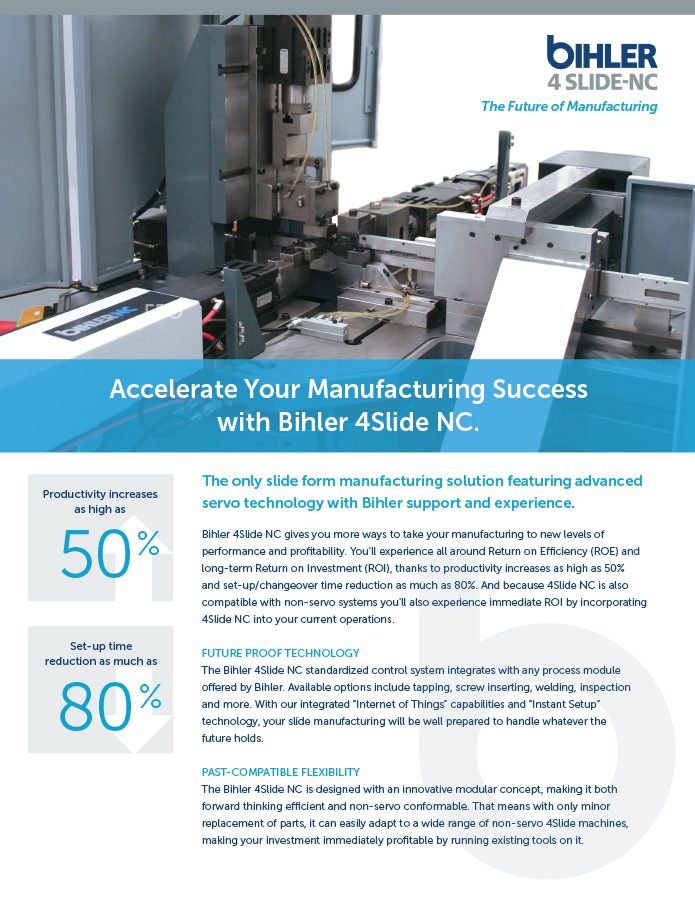

Bihler 4Slide-NC gives you two very important ways to accelerate your four slide manufacturing success. You’ll experience all around Return on Efficiency (ROE) and long-term Return on Investment (ROI) thanks to productivity increases as high as 50% and conversion time reduction as much as 80%. And because 4Slide-NC is also compatible with non-servo systems you’ll also experience immediate ROI by incorporating 4Slide-NC into your current operations.

Bihler 4Slide-NC gives you two very important ways to accelerate your four slide manufacturing success. You’ll experience all around Return on Efficiency (ROE) and long-term Return on Investment (ROI) thanks to productivity increases as high as 50% and conversion time reduction as much as 80%. And because 4Slide-NC is also compatible with non-servo systems you’ll also experience immediate ROI by incorporating 4Slide-NC into your current operations.

The Bihler 4Slide-NC standardized control system integrates with any process module integration offered by Bihler. Available options include tapping, screw inserting, welding, inspection and more. With its integrated “Internet of Things” capabilities and “Instant Setup” technology, your four slide manufacturing will be well prepared to handle whatever the future holds.

The Bihler 4Slide-NC standardized control system integrates with any process module integration offered by Bihler. Available options include tapping, screw inserting, welding, inspection and more. With its integrated “Internet of Things” capabilities and “Instant Setup” technology, your four slide manufacturing will be well prepared to handle whatever the future holds.

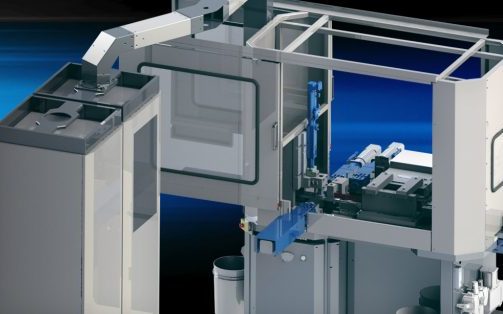

The Bihler 4Slide-NC is designed with an innovative modular concept, making it both forward-thinking efficient and non-servo conformable. That means with only minor replacement of parts, it can easily adapt to a wide range of non-servo four slide machines, making your investment immediately profitable by running existing tools on it.

The Bihler 4Slide-NC is designed with an innovative modular concept, making it both forward-thinking efficient and non-servo conformable. That means with only minor replacement of parts, it can easily adapt to a wide range of non-servo four slide machines, making your investment immediately profitable by running existing tools on it.

Bihler 4Slide-NC

Bihler 4Slide-NC is the only manufacturing solution providing advanced four slide servo technology backed by Bihler’s years of global expertise and experience.

Our next-generation servo-driven four slide machines will elevate your manufacturing success to unmatched levels of productivity and operational efficiency with features and benefits that include:

- Highly efficient production of strip, spring and wire parts in large or small batch sizes

- Extremely short set-up times

- 15″ TFT touch screen for user-friendly operation, enabling virtually instant cam changes

- Reduced tool costs and debugging time

- Full tool compatibility to select mechanical four slide machines

- Multiple storage areas for easy access to tool setups

Integrated process and production monitoring - Faster production speeds

- Rapid response to short-term customer requests

- Lot sizes processed in half the time

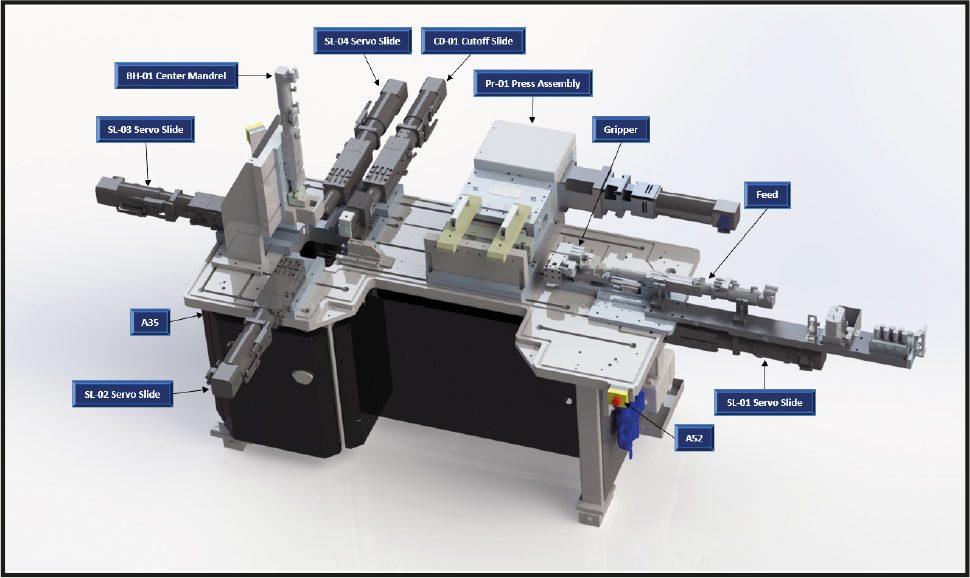

| Production Speed (per minute) | Variable/0–250 |

| Forming Slide | |

| Cutoff Slide | 2 Tons/1.0″ Stroke |

| Mandrel | 0.5 Tons/4.7″ Stroke |

| Auxiliary (optional) | 0.5 Tons/4.7″ Stroke |

| 7 Ton Press | 7 Tons/0.75″ Stroke |

| 14 Ton Press | 14 Tons/0.75″ Stroke |

| 21 Ton Press | 21 Tons/0.75″ Stroke |

| 28 Ton Press | 28 Tons/0.75″ Stroke |

| Servo Gripper Feed | Maximum 9.4″ |

| Caterpillar Feed | No End Termination |

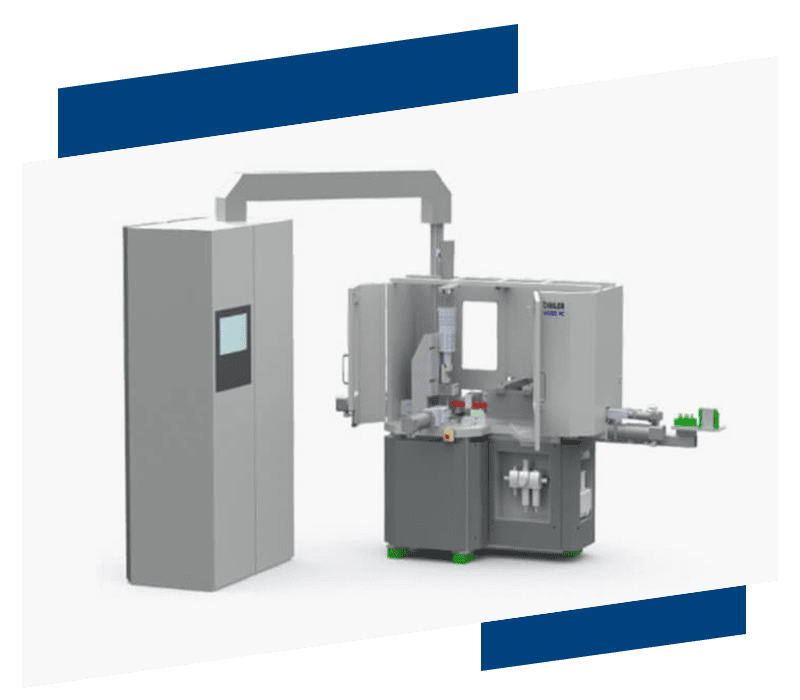

The Bihler 4Slide-NC is equipped with the VariControl VC1. Installed in a stand-alone control cabinet, it offers simple operation and programming of the individual control and servo modules via an operating panel with 15” TFT touch screen. This highly intuitive control can support all the automation tasks needed to accelerate your manufacturing success.

The Bihler 4Slide-NC is equipped with the VariControl VC1. Installed in a stand-alone control cabinet, it offers simple operation and programming of the individual control and servo modules via an operating panel with 15” TFT touch screen. This highly intuitive control can support all the automation tasks needed to accelerate your manufacturing success.

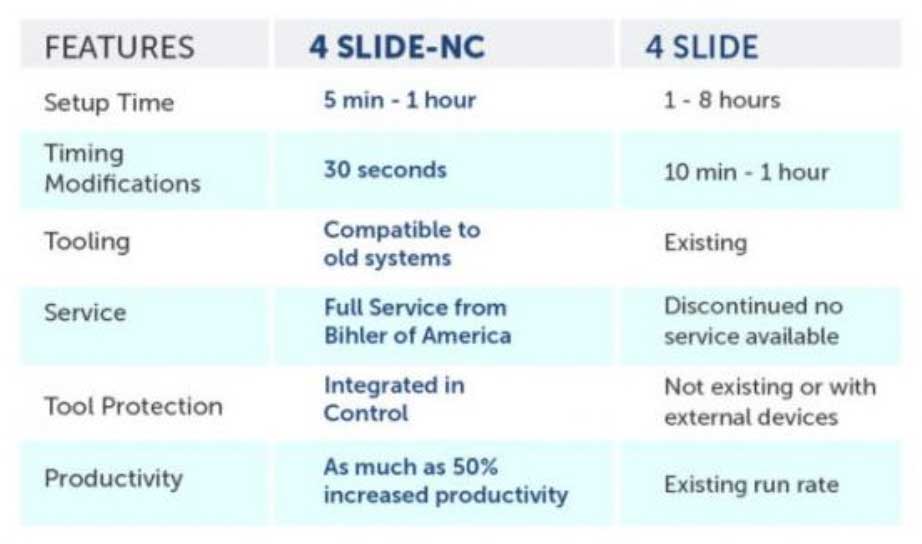

Compare next generation Bihler 4Slide-NC servo technology with traditional four slide manufacturing equipment and discover how to dramatically reduce lot run time, get better process control and increase productivity as much as 200%.

Servo Processing Modules |

Infosheet – Bihler 4 Slide NC |

Brochure – 4Slide-NC |

Frequently Asked Questions

Our Credentials

Certified Women’s Business Enterprise National Council

ISO9001:2015 Certified (Bihler)

Medical Quality Standard: ISO 13485 (BihlerMed)

Automotive Quality Standard: IATF 16949–Innospin